8 READ-TIME

The complexities of creating a new hybrid canola

January 2, 2024

By Jennifer Barber

Believe it or not, what ends up as about 4.25 million seeds in a bag of DEKALB, started out about three years earlier as a few grams of breeder seed in a small envelope. How that tiny amount of seed scales up to commercial quantities involves precision, careful controls and well-planned processes that maintain breeding integrity every step of the way.

“Plant breeding has now caught up to where animal breeding has been for a while,” says Dale Burns, product development breeder, canola, with Bayer. “With our current knowledge of genetics everything is less a breeder guess and more planned out. We are able to use genomics to know what outcomes are likely and this has cut down the breeding process by a few years. Everything about plant breeding is about how big the numbers are, how reliable the traits are and how fast we can get those genetic gains into a new product.”

Getting from that initial envelope of breeder seed to a bag of hybrid canola takes about three years and involves three main steps: breeding quality genetics, producing parental lines and commercialization of each hybrid seed.

STEP 1: Breeding quality genetics

STEP 3: Taking a hybrid to commercialization

Each female and male line of foundation seed is then shipped to Bayer’s site in Lethbridge, AB. There, the parental lines are cleaned, treated and packaged, ready for seeding on contracted fields with seed growers. The goal is to produce multiple hybrids to meet customer demand each season.

“We contract with local growers to grow on 130-acre irrigated pivot circles,” says Robert Wauters, site lead at the Bayer’s commercial production and breeding site in Lethbridge. This is not traditionally a large canola growing region, so the team is able to geographically isolate new hyrbids from other canola fields to maintain purity. By using contract growers under irrigation, they are also able to mitigate some of the weather risk of growing canola, in an area with a long growing season.

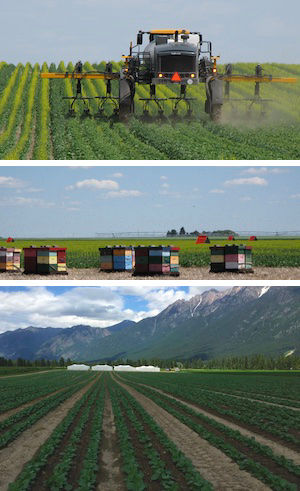

“Each field is row cropped with four rows of female seed, and one row of male seed alternating across the width of the field,” says Wauters. “We contract with local honeybee and leafcutter beekeepers to pollinate the crop. We also use specialized high clearance field equipment to trim the parent lines to keep the flowers in the male and female lines synchronized.”

He explains that they use the same machinery with a different header to specifically cut the male rows out of the field as this is not seed they want — hybrid seed is produced by the sterile female lines that have been crossed with pollen from the male lines.

When those plants produce pods, they are swathed and combined using normal farming methods. During the winter months, the Lethbridge crew run the harvested seed through their onsite commercial cleaning plant, then send it out to be treated and bagged at third party contract facilities.

“Each contract field will yield more than 100 metric tonnes of canola seed,” says Wauters. “Part of the magic of hybrid canola is its incredible ability to multiply. In a span of just a few years you can go from just a coin envelope of breeder’s seed to over 100 metric tonnes of hybrid canola that meets the agronomic and trait specifications of the hybrid first created by the breeder.”

“We are continually pushing to grow the highest yielding, highest quality commercial canola hybrids each season,” says Wauters. “This year we will be producing at least 12 canola hybrids. With more agronomic traits attached to a variety of herbicide tolerance systems, we are continually working to meet the demands of our canola seed customers.”