3 READ-TIME

Monitor Black Layer to Guide Corn Harvest

October 13, 2020

Physiological Maturity in Corn

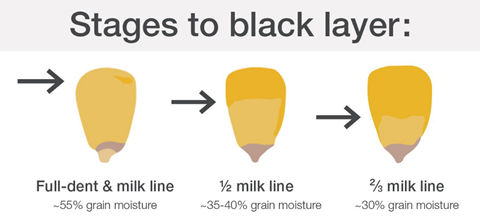

Corn kernels achieve black layer or physiological maturity when a black film develops at the tip of a kernel. The black film or layer seals the kernel from further development or increase in test weight. The kernel moisture content at black layer formation usually ranges from 30% to 35% (Figure 1).1

Figure 1. As the milk line diminishes, moisture drops from 55% to near 30% moisture. The formation of a black layer where kernels meet the cob signifies physiological maturity.

Physiological maturity is greatly influenced by the relative maturity (RM) of the individual corn product. Short-season products mature earlier than full-season products. This genetic characteristic allows for the selection and planting of different corn products to spread out (over time) the maturation of a farming operation’s corn crop. This helps with harvest scheduling as all corn acres are not maturing at the same time.

Effects of Stress on Corn

Environmental stress can affect the timing of maturation. Severe drought can cause plants to die prematurely and kernels to form a premature black layer. Cool weather during the growing season can delay the normal maturation for an individual product because the corn heat units (CHUs) required to achieve maturity accumulate slower.

Grain Moisture and Harvest Timing

Grain moisture content should start to be monitored soon after physiological maturity (black layer). A harvest moisture content level that balances harvest losses and grain drying costs helps maximize the economic return potential. A plan to take advantage of a rapid drydown and allow everything to field dry could be costly. Harvesting at lower moistures can increase mechanical losses due to ear drop, stalk lodging, and kernel shattering. Consider beginning harvest when corn grain moisture content is a little above 25% so harvesting can be finished before corn dries completely in the field.1

With high temperatures, it is extremely easy to underestimate the rate that grain dries. Grain can have an average daily drydown rate of approximately 0.75 to 1.0 percentage point on sunny and breezy days in September. A 0.25 to 0.75 daily percentage point loss can be expected in October, and almost no moisture is lost by late November.2 Regardless of the environment, it is normal to see later RM corn products reach harvestable moisture levels (around 25%) later than earlier RM products. Product drydown rates are influenced by many product characteristics, such as tightness of husk leaves and pericarp thickness of the seed.3

In addition to harvesting at an optimum grain moisture content, achieving proper combine settings can help increase combine efficiency, maximize grain quality, and minimize field losses. Always follow the manufacturer’s equipment setting recommendations.

Sources:

1 OMAFRA Staff. 2018. Corn. Agronomy Guide. Pub 811.

2 Thomison, P. 2019. Drydown in corn – what to expect? The Ohio State University. Knox County Agricultural News.

3 Nielsen, R.L. 2018. Field drydown of mature corn grain. Corny News Network Articles. Purdue University. https://www.agry.purdue.edu/ext/corn/news/timeless/GrainDying.html. Web sources verified 9/18/20.

Legal Information

Performance may vary from location to location and from year to year, as local growing, soil and weather conditions may vary. Growers should evaluate data from multiple locations and years whenever possible and should consider the impacts of these conditions on the grower’s fields.

©2020 Bayer Group. All rights reserved. 7005_S5

La performance peut varier d'un endroit à l'autre et d'une année à l'autre, compte tenu des variations locales dans les conditions de croissance, de sol et de climat. Si possible, les producteurs devraient évaluer les résultats de plusieurs sites et années et devraient tenir compte des conséquences de ces conditions sur leurs champs.

©2020 Groupe Bayer. Tous droits réservés.