4 READ-TIME

Best Application Practices for VaporGrip® Technology Herbicides in Roundup Ready 2 Xtend® Soybeans and XtendFlex® Soybeans

October 19, 2022

Note: This document does not replace the herbicide labels that MUST be read and followed.

Roundup Xtend® herbicide with VaporGrip® Technology*, Roundup Xtend 2™ herbicide with VaporGrip® Technology, XtendiMax® herbicide with VaporGrip® Technology, and XtendiMax 2™ herbicide with VaporGrip® Technology contain a dicamba formulation that reduces potential dicamba volatility and are designed to be used with Roundup Ready 2 Xtend® soybeans (tolerant to dicamba and glyphosate) and XtendFlex® Soybeans (tolerant to dicamba, glyphosate, and glufosinate).

The herbicides and herbicide tolerant soybeans form the foundation of the Roundup Ready® Xtend Crop System. The herbicides can be applied pre-plant, at planting, pre-emergence, and post-emergence up to and including the beginning of bloom (R1). The dicamba formulations improve early weed control including tough-to-manage and glyphosate-resistant (GR) weeds within the Roundup Ready® Xtend Crop System.

Roundup Xtend® herbicide with VaporGrip® Technology* (Group 4 and 9) and Roundup Xtend 2™ herbicide with VaporGrip® Technology (Group 4 and 9) are glyphosate and dicamba pre-mix formulations with low volatility properties. Roundup Xtend 2™ herbicide with VaporGrip® Technology is a more concentrated formulation (Table 1).

*Roundup Xtend® herbicide with VaporGrip® Technology is being replaced in the marketplace with Roundup Xtend 2™ herbicide with VaporGrip® Technology. It is used in this document for rate comparisons.

XtendiMax® herbicide with VaporGrip® Technology (Group 4) and XtendiMax 2™ herbicide with VaporGrip® Technology (Group 4) are dicamba straight-good herbicides with low volatility properties designed to be tank-mixed with the glyphosate-only herbicides Roundup WeatherMAX® herbicide (Group 9) or Roundup Transorb® HC herbicide (Group 9). Used alone, the herbicides mainly manage broadleaf weeds. Grass control occurs when tank-mixed with the glyphosate-only products. XtendiMax 2™ herbicide with VaporGrip® Technology is a more concentrated formulation (Table 2).

Table 1. Concentration comparison between Roundup Xtend® herbicide with VaporGrip® Technology and Roundup Xtend 2™ herbicide with VaporGrip® Technology.

| Herbicide | Glyphosate (monoethanolamine salt) | Dicamba (diglycolamine salt) |

|---|---|---|

| Roundup Xtend® with VaporGrip® Technology | 240 g a.e./L | 120 g a.e./L |

| Roundup Xtend 2™ with VaporGrip® Technology | 317 g a.e./L | 159 g a.e./L |

| Herbicide | Dicamba (diglycolamine salt) |

|---|---|

| XtendiMax® with VaporGrip® Technology | 350 g a.e./L |

| XtendiMax 2™ with VaporGrip® Technology | 474 g a.e./L |

Application Recommendations

Early application (pre-plant to early post at the soybean V2 growth stage) using the high labeled rate for each herbicide is recommended for best results. The risk of off-target movement is minimized due to the use of VaporGrip® Technology.

Roundup Xtend® herbicide with VaporGrip® Technology and Roundup Xtend 2™ herbicide with VaporGrip® Technology

- High Rate

Roundup Xtend® herbicide with VaporGrip® Technology – 2 L/acre (5 L/ha) Roundup Xtend 2™ herbicide with VaporGrip® Technology – 1.5 L/acre (3.77 L/ha) This rate, which can be used only once per season, can be used pre-plant, pre-emergence, or in-crop early post-emergence to manage emerged weeds and can provide up to 14 days of residual broadleaf control.

XtendiMax® herbicide with VaporGrip® Technology and XtendiMax 2™ herbicide with VaporGrip® Technology

- High Rate

XtendiMax® herbicide with VaporGrip® Technology – 0.7 L/acre (1.71 L/ha) XtendiMax 2™ herbicide with VaporGrip® Technology – 0.5 L/acre (1.23 L/ha) This rate, which can be used only once per season, can be used pre-plant, pre-emergence, or in-crop early post-emergence to manage emerged weeds and can provide up to 14 days of residual broadleaf control.

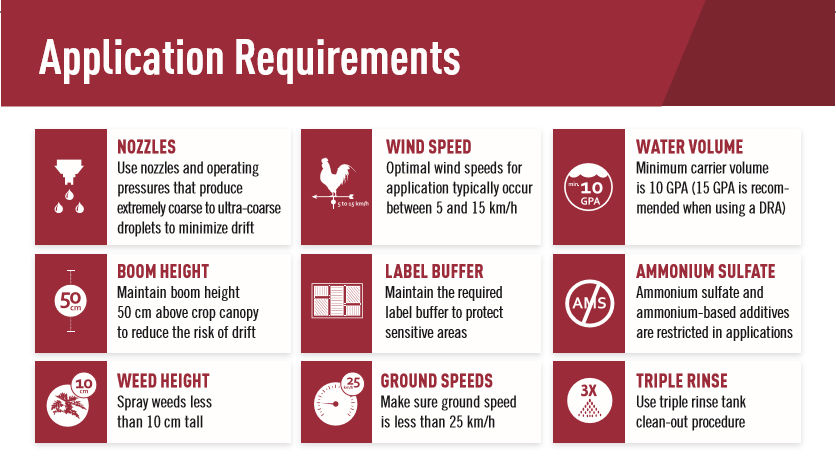

Application Requirements

The full set of application requirements must be followed to increase the spray accuracy and efficacy of the Roundup Ready® Xtend Crop System herbicides. The application requirements outline the correct usage of the herbicides including specifications for droplet size, wind speed and direction, boom height, weather conditions, sensitive crop buffers, and other variables to help maximize on-target application.

Key Label Application Requirements

- Ensure that the entire sprayer system is properly cleaned before AND after applying the VaporGrip® Technology herbicides to avoid contamination.

- Use only nozzles and operating pressures that produce extremely coarse to ultra-coarse droplets to minimize drift.

- Use a minimum of 100 L/ha (10 GPA) of spray solution for optimal performance. It is recommended to increase the application volume to 150 L/ha (15 GPA) when targeting large weeds or using a drift reduction additive (DRA).

- Spray early when weeds are less than 10 cm (4 inches).

- Keep boom height less than or equal to 50 cm (20 inches) from the target crop or weed to help ensure on-target spray accuracy and help minimize the risk of off-target movement.

- Do not exceed a ground speed of 25 km/hr (15.5 MPH).

- Apply when wind speed, measured at boom height, is between 5 and 15 km/h (3 and 9.3 MPH) and blowing away from sensitive areas or crops (Table 3).

- DO NOT spray during a TEMPERATURE INVERSION. Signs of a temperature inversion include almost no wind or dead calm, dew or frost, mist or ground fog, and smoke moving mostly horizontally at a relatively low height. (A temperature inversion can occur when cold air at ground level is trapped by warm air above. This condition can cause fine droplets to form a concentrated cloud which can move via light winds. These conditions typically occur in the evening around dusk and often remain through the night until sunrise. As the ground warms and winds increase, the inversion is dispersed, and the droplets disperse normally.)

- Use only approved tank-mix partners. DO NOT use ammonium sulfate (AMS) or other ammonium-based additives or fertilizers.

- DO NOT add water conditioners or buffering agents that acidify the spray solution.

- Avoid application when the temperature is expected to exceed 30° C (86° F).

| Wind Speed | Application Condition and Restrictions |

|---|---|

| < 5 km/hr (3.1 MPH) | DO NOT apply if temperature inversion exists |

| 5 to 15 km/hr (3.1 to 9.3 MPH) | Optimum application conditions |

| > 15 km/hr (9.3 MPH) | DO NOT apply |

Important steps to follow in the application process are outlined in Figure 1, which is not a substitute for reading and following the product labels and complete application requirements.

Figure 1. Application requirements for VaporGrip® Technology herbicides (alone or in a tank-mix).

Off-target Movement

It is crucial to consider the contributing factors for off-target herbicide movement. The potential for off-target movement exists during any herbicide application, not just with dicamba. Physical drift, sprayer contamination, and volatility are the three major types of off-target movement.

Physical drift is the physical movement of spray droplets during application and mostly involves wind but can also occur in a temperature inversion (see temperature inversion under Key Label Application Requirements).

Sprayer contamination usually occurs when the same sprayer is used to treat different crops with different herbicides. The entire system must be cleaned thoroughly before a different herbicide solution is added to the tank as some herbicides act as cleaners and can release imbedded particles into the solution. If the cleaning process is not completed thoroughly, herbicide residue can remain in tanks, pumps, hoses, and nozzles and be unintentionally applied to sensitive crops in the next herbicide application.

Volatility, the least common form of off-target movement, occurs when an herbicide changes from a liquid into a vapor state after application and moves away from the target application area. The risk of volatility is often dependent on factors such as the chemical properties of the formulation, the boiling point, and the ambient temperature during and after the application. It is sometimes referred to as secondary drift because the injury is often noticed several weeks or more after application. In many cases, this injury may have been caused by spray droplet drift, which at low levels can also take several weeks for injury symptoms to appear because the symptoms appear on new growth. VaporGrip® Technology herbicides are less volatile than older dicamba formulations.

For VaporGrip® Herbicide labels, additional information on off-target movement, and proper application requirements for VaporGrip® Technology Herbicides, please visit:

https://www.cropscience.bayer.ca/Products.

Legal Statements

Bayer is a member of Excellence Through Stewardship® (ETS). Bayer products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Bayer’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. These products have been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from these products can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for these products. Excellence Through Stewardship® is a registered trademark of Excellence Through Stewardship.

ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. Performance may vary from location to location and from year to year, as local growing, soil and weather conditions may vary. Growers should evaluate data from multiple locations and years whenever possible and should consider the impacts of these conditions on the grower’s fields.

It is a violation of federal law to use any pesticide product other than in accordance with its labeling. NOT ALL formulations of dicamba or glyphosate are approved for in-crop use with products with Roundup Ready 2 Xtend® soybeans. NOT ALL formulations of dicamba, glyphosate or glufosinate are approved for in-crop use with products with XtendFlex® Technology. ONLY USE FORMULATIONS THAT ARE SPECIFICALLY LABELED AND APPROVED FOR SUCH USES. Contact the Pest Management Regulatory Agency with any questions about the approval status of dicamba herbicide products for in-crop use with Roundup Ready 2 Xtend® soybeans or products with XtendFlex® Technology.

Products with XtendFlex® Technology contains genes that confer tolerance to glyphosate, glufosinate and dicamba. Roundup Ready 2 Xtend® soybeans contains genes that confer tolerance to glyphosate and dicamba. Glyphosate will kill crops that are not tolerant to glyphosate. Dicamba will kill crops that are not tolerant to dicamba. Glufosinate will kill crops that are not tolerant to glufosinate. Contact your Bayer retailer, refer to the Bayer Technology Use Guide, or call the technical support line at 1-888-283-6847 for recommended Roundup Ready® Xtend Crop System weed control programs.

Tank mixtures: The applicable labeling for each product must be in the possession of the user at the time of application. Follow applicable use instructions, including application rates, precautions and restrictions of each product used in the tank mixture. Bayer has not tested all tank mix product formulations for compatibility or performance other than specifically listed by brand name. Always predetermine the compatibility of tank mixtures by mixing small proportional quantities in advance. Bayer, Bayer Cross, Roundup Ready 2 Xtend®, Roundup Ready 2 Yield®, Roundup Ready®, Roundup Transorb®, Roundup WeatherMAX®, Roundup Xtend®, Roundup Xtend 2™, VaporGrip®, XtendFlex®, XtendiMax® and XtendiMax 2™ are trademarks of Bayer Group. Used under license. LibertyLink® and the Water Droplet Design™ are trademarks of BASF. Used under license. All other trademarks are the property of their respective owners. Bayer CropScience Inc. is a member of CropLife Canada. ©2022 Bayer Group. All rights reserved. 1326_47929